Table of Contents

TheLab Bambu 3D Print Quick Start

As usual this detailed guide is subject to change so, for personal and machine safety, please ask an experienced lab member to assist in helping you through your first couple of uses.

The Bambu Labs Wiki

The Design Process Overview

There area just a few steps required before you to can successfully print your first 3D design.

- Design your project within a CAD 3D print design software

- Import the design into your local version of Bambu Studio, the software that drives the actual machine. This is not required but is recommended for your initial designs so can become familiar with the usage of Bambu Studio.

- Take your design to TheLab computer and version of Bambu Studio for the actual print process.

The Design

There are a number of 3D print design/CAD software packages that can be used to create/modify your design such as TinkerCad, Blender, FreeCad, Fusion, etc. We will not attempt to detail them here.

- After your design is complete export the design file in a format acceptable to Bambu Studio.

The Printers

The Lab currently has 2 of the Bambu X1 Carbon printers, know as “Giga” and “PLA Only”.

- As named, the “PLA Only” printer should be used only with PLA filament.

- The “Giga” printer can be used with most other filament types.

Both printers have attached to them a 4 spool AMS, Automatic Material System“ option. This facilitates automatic switching of the available filament. Initially this guide will not cover AMS usage.

The Driving Software

Bambu Labs “Bambu Studio” is the software used to actually drive the printing process.

If you are not familiar with Bambu Studio it is recommended you install the software on your local machine. Although this will not allow you to actually connect to the physical machines, it will give you an opportunity to become familiar with the product at your leisure.

A good place to start is the Bambu Quick Start Guide which will step you through the installation and general usage of the product.

This can be followed up with the following which may add to information contained within the quick start.

- Bambu Studio Beginner Tutorial: Learn the basics: https://www.youtube.com/watch?app=desktop&v=kck5jv2-uao

- Bambu Studio Keyboard Shortcuts: https://wiki.bambulab.com/en/software/bambu-studio/3d-scene-operations

Member local Bambu Studio

Once one is comfortable one can perform these steps on the Lab machine version of Bambu Studio if desired.

Preparing/Previewing/Slicing at home or in TheLab

You will repeat most these steps at the Lab, running through them at home will help you become familiar with the studio product at your leisure. Once comfortable with the tool it is perfectly acceptable to perform these steps on the Lab machine. The final configuration will depend on the Lab machine setup

- The first step is to To import the your design file. Supported files include .3mf .stl .stp .step .amf .obj.

- Click File→import→import 3MF/STL/STEP/…

- The Prepare Tab should automatically open with your project displayed in the center of a print plate.

- Note and Correct any errors reported by the Studio

The Prepare Tab

- Select Printer Type, Bambu Lab X1, (Nozzle size will depend on what you printer has installed)

- Select Plate Type, depending on type type of filament.

- NOTE: Selecting an incompatible print plate may affect how well an object adheres to the print plate.

- Bambu Plate Types: https://wiki.bambulab.com/en/filament-acc/acc/plates

- Add/select your filament. For this if you are not sure if using PLA you can choose Bambu PLA Basic. The following Bambu wiki gives a good overview of filament types/usage:

- Bambu Filaments and Accessories: https://wiki.bambulab.com/en/filament-acc

- Filament guide - Compatibility to printer, nozzle, AMS, build plate, glue and required parametes https://wiki.bambulab.com/en/general/filament-guide-material-table

* The remaining items can be left to default until you are more familiar with the process. The default settings should be fine for your first print if it is not too complicated.

The Preview tab

- Select the “Preview” tab

- Note and correct any errors, add supports to your project if needed.

- Use the mouse scroll wheel to zoom in and out, left button to view the object from different perspectives, right mouse button to reposition the plate within the view port.

- Bambu Studio Keyboard Shortcuts: https://wiki.bambulab.com/en/software/bambu-studio/3d-scene-operations

Slice your model

- Press the Slice Plate button on upper right to start the slicing process

- Bambu Studio - Complete Beginner’s Guide to Slicing for 3D Printing : https://www.youtube.com/watch?v=xUi54VpSeek

- Note and correct as needed any reported errors/warning

- If successful a dialog containing “Slice ok” should be displayed. Also you will find a “Color Scheme” chart that indicates various characteristics of the pending print process

If the slicing process notes any errors/concerns they will be presented. One example is if your design needs “supports” to aid in printing parts that hang out over space, unsupported. These you would need to trim from your final product.

More about Supports

* How to create automatic or manual supports: https://www.youtube.com/watch?v=-CUSWpVZsUY * Normal vs. Tree Supports: https://www.youtube.com/watch?v=RXVVvZciR9Q

Save/Export Your Project

When done previewing/defining/slicing your project settings on your personal copy of Bambu Studio, save your changes to your thumb drive. There are a couple of ways you can do this,

Save the Project

To save as a full project, select “File→Save Project”.

Then you can reload the project within the Lab version of Bambu Studio. This will allow you to modify any of your model and printer characteristics. You may need to “reset” some of the characteristics set when viewing your model in your personal version.

Export the data

To export the file data, select “File→Export”.

There are several formats which you can choose when exporting, not all of which may be enabled.

- If you use the export as G-code it is not obvious to the author how you can change print characteristics such as nozzle size, filament type, etc.

- If you export as a .stl file you can take it to a design program but if you re-import within Bambu Studio will need to repeat the Prepare/Preview steps performed in you personal version.

Whatever form you chose it can be taken to TheLab to be loaded on the Lab version of Bambu studio.

This will become less burdensome once you become comfortable using the Bambu Studio. Then perhaps you can do the entire workflow within the Lab version, most likely after one or two print cycles.

Makerspace Bambu Studio

Visually inspect the printers to ensure one is available for use before continuing, otherwise this may just waste your time.

- login on to the Lab's silver mini computer located in the atrium area next to the book cases, pin code is on the lower right hand side of the monitor. Note: The computer in the print room also has Bambu Studio loaded but it is “not” connected to the printers at this time.

- If someone has an instance of Studio already running and is monitoring a current print job, do not interrupt the job in progress. You can however open a second instance of Bambu Studio targeting the available printer.

On Lab machine, within Bambu Studio

DO NOT log into the Bambu Labs internet site within Bambu Studio with your personal Bambu Lab account. Doing so will prevent the normal print process. The generic Lab account must be used

Do not update the Lab version of Bambu Studio if presented with the option. Confer with the area coordinator and via the “Bambu” discord channel if you have version concerns.

- Insert your thumb drive, then import the file you saved at home, the original .stl, gcode, or what ever format Studio will accept.

* Do NOT attempt to login in to your own personal Bambu account. - EDITOR NOTE: Clarify what login

- Doing so will logout the Lab shared 3d printing account tied to the Bambu printer in the lab.

- EDITOR NOTE: Whom to contact if not currently logged in?

On the Prepare Tab

- Verify the project settings, printer, build plate, filament, etc are acceptable

- Refer to the “Member local Bambu Studio” section if you need a refresher of the particulars.

On the Device Tab

Here you can select and set as needed your printer characteristics corresponding to the available printer. * You can “get” the current state of the selected printer to determine it's characteristics

* EDITOR NOTE: MORE NEEDED FOR CHARACTERISTICS

- Double check that the printer currently selected is the desired idle printer.

- The dialog will show the expected print duration and filament consumed.

- The initial default settings, other than printer selection, should be fine until you are more familiar with the implications.

On the Preview Tab

- select the “Preview” tab

- Note and correct any errors

- Refer to the “Member local Bambu Studio” section if you need a refresher of the particulars.

* click “Slice Plate” to slice the file - Bambu Studio - Complete Beginner’s Guide to Slicing for 3D Printing : https://www.youtube.com/watch?v=xUi54VpSeek

Prepare Machine for Printing

Visually inspect the printer to ensure one is still available for use before continuing.

- The printers are intended to remain on at all times. So they should not be turned off.

Filament

- verify filament currently installed on machine

- One can use “Lab” filament for the current price of .03 cents per gram.

- There is a scale by the machines

- There is a payment QR code on the wall between the machines

- Members who bring their own filament are encouraged to label their rolls as unlabeled rolls are considered fair game. “Lab” rolls are typically not labeled as such

- Extra lab rolls can be found in one of the bins marked as such below the printers

Plate Type

First a some “plate” definitions

Heat Bed

- This is the non removable print plate that contains a heating element which varies in temperature depending on filament type used. Proper temperature helps to ensure a successful print.

- This plate should never come in contact with any foreign substance be it filament, glue, etc.

- You must ensure there is a magnetically attached print plate on the heat bed before attempting a print.

Print Plate

- This is thin removable, magnetically attached plate that is place on top of the heat bed. Different plate designs have been developed to enhance the print process/success rate. These plates are designed to be removable for easier cleaning and occasional replacement if necessary.

- NOTE: Some print filaments/procedures may suggest placing glue or some other substance on the print plate to aid in filament adhesion. DO NOT allow such substance to come in contact with the heat bed. Before attaching a print plate please ensure the side that contacts the heat bed is of free of foreign substances. Better yet clean the print plate before using to ensure maximum print adhesion and to avoid contaminating the heat bed.

- Choose a print plate appropriate for your project and allow it to magnetically attach to the heat bed.

- Bambu Plate Types: https://wiki.bambulab.com/en/filament-acc/acc/plates

Clean the Print Plate

The print plates should be inspected and cleaned if necessary before using. The following are some how tos:

- Bambu Lab Textrued PEI Plate Cleaning Guide: https://wiki.bambulab.com/en/filament-acc/acc/pei-plate-clean-guide#:~:text=After%20applying%20the%20dishwashing%20detergent,the%20plate%20from%20the%20sides.

- How to Clean Bambu Lab Cool/PLA Print Plate: https://www.youtube.com/watch?v=s93wR_DHtdk&t=90s

Send Print Job to Machine

If the printer is ready to go, the slicing within Studio is successful and the available printer is selected within Studio then one can “Send” the job to the printer. Sending involves uploading the project to the Bambu cloud from which it will then be sent to the selected printer.

Within Bambu Studio, Preview tab

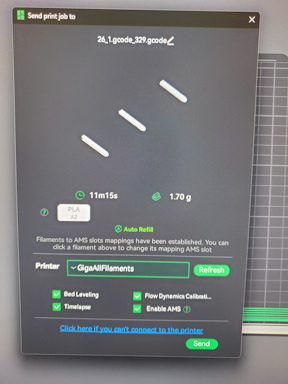

- If the slicing is complete and successful, click on the “Print Plate” menu item at the top right of the window. The following “Send print job to” dialog will be displayed.

Here you can verify the print configuration about to be sent to the printer. Verify the settings/information presented is correct for your project

- Estimated time and filament used for the job

- Selected filament position within the AMS. This is important if there are other filaments loaded that may be a better match to the filament set in the project than the filament you may have manually loaded.

- Currently selected printer name

- Printer initialization options

If those settings are correct, proceed by selecting the “Send” button.

- A progress bar at the bottom of the dialog will show upload progress.

- When the “send” is complete, the Device tab will display a camera view along with the expected print time and filament to be consumed.

- Click on the green arrow on the left mid screen to turn on the video view.

The following Bambu Lab link will provide further printing details.

- NOTE: In spite of this documents suggestion DO NOT log into the Bambu Labs internet site within Bambu Studio using your personal Bambu Lab account. Doing so will prevent the normal print process. The generic Lab account must be used

- Printing from Bambu Studio: https://wiki.bambulab.com/en/p1/manual/print-from-bambu-studio

At the printer

Once the “send” has completed the printer will run through several phases before actually starting to print your project. The bed needs to be heated, printer bed leveled, printer calibrated. You can monitor these automatic phases at the printers control panel as seen below:

The following video will give a walk through of the printer's GUI control panel.

- Graphic User Interface WALKTHROUGH: https://www.youtube.com/watch?v=3LQCO8PTMxc

Verify filament being used

With the AMS system it is easy for your project desires to be out of sync with the actual printer settings.

Perhaps your project is set to use the filament within position 1 of the AMS. When you get to the Lab you might see an empty position and accidentally load your filament in position 2. Then you initialize the filament load process at the printer itself to load your filament from position 2.

When you send the print job within Bambu Studion it will do what your “program” says, it will switch to AMS position 1 for the print. Probably not what you had intended.

This may occur also if your print job filament “type” does not match what is currently in the job specified AMS position, but is available in a different AMS position.

It's also a good idea to monitor your print job at least in the early stages to ensure it is adhering to the print plate as expected.

Completing Print

One your print is complete the Device tab within Studio will display a print complete status message.

- Don't forget to close “YOUR” instance of Bambu Studio”. When doing so discard any “modified values” to prevent any global Studio changes from affecting other members.

- Make sure you do not close another other instances which may be controller other members unattended print jobs.

Remove you finished print

Generally you can remove your printed job from the print plate via a finger nail scrape, if that proves problematic there are “plastic” scraper tools located in one of the drawers between the printers.

- Under no circumstances is it acceptable to use metal tools on these print plates, that will damage them rendering them unusable.

Miscellaneous things that might be useful

Just a collection of interesting things

Skip an object

If one is printing multiple objects at the same time, occasionally one or more objects may fall over or become separated from the print plate. This can result in a whole bunch of print “poop”. If this is the case one or more objects in the print job can be skipped as described in the Bambu Labs article:

Just one of several video showing how to skip an object at the printer control screen